The Global Excellence Team Limited is a United Kingdom registered organisation started by Kola Olutimehin and David Hutchins, who later invited some other Quality Improvement consultants and trainers who have worked across different parts of the world, implementing whole company-wide management systems, which have been uniquely successful. During this work, we have become associated with many specialists in all areas of the subject, who together with the Principals, can match any consultancy and training organisation in the world in this subject area.

This specialisation in TQM extends far beyond most Western people’s perception of the subject, which is often restricted to operational practices. Further, this perception leads to viewing an organisation in its role in their market place as having to deal with competition that would willingly destroy its rivals, given the opportunity. We can help our clients to reverse this situation, making them formidable forces to confront in their chosen marketplace!

- We achieve this through the implementation of a culture changing concept known in Japan as Culture of the Business Strategic Structure. This is called Hoshin Kanri, and it has successfully sent huge numbers of its foreign rivals to the global corporate graveyard!

- Quality Circles (also known as ‘Quality Control Circles’ or ‘Self-Managing WorkGroups’), which individually, might only produce modest returns on their activities, but collectively company-wide, they can yield tremendous results, and we can help our clients achieve that.

We partner with our global clients and professional/mature associates to transform organisations, with a drive to help them improve business performance well beyond their expectations. We are driven to take Quality Beyond Borders.

Hoshin Kanri

Our approach to Hoshin Kanri is founded on the observation that business performance improvement is more like sweeping the stairs (of which we start from the top) than attempting to light fires (starting from the bottom), which is the flawed approach that has been used by many who have failed. We have found that starting from the top, working initially with the top executive team, is the only approach that proves successful. The only risk of failure this way is through a change of CEO, to one who has not adopted the culture!

Following this, by training ‘would-be’ trainers, and training trainers to train other ‘would-be’ trainers, we can transfer our skills and knowledge into the resources of the client, whilst helping business leaders to incorporate the principle of cascading their vision. Our coaching skills are employed to business leaders to help create their vision statements, which are then followed by a series of Mission statements, goals and objectives all the way down to the workforce.

Hoshin Kanri is a strategic approach to continuous improvement that embraces TQM, and provides a context for all of the individual elements of problem-solving frameworks such as, Lean, Six Sigma or Business Process Reengineering.

In summary, we guide business leaders to:

- Develop a dynamic vision for continuous improvement;

- Implement effective policies to support it;

- Link key performance indicators to different types of problem-solving methodologies that their organisation is attuned to, and

- Sustain a strategy-led programme for improving business performance.

Quality Circles

Our implementation plan for Quality Circles, is founded on the Japanese approach to business management in which the skills creativity and job knowledge of all the employees is concentrated on making their company the best in its business.

In the recently published book written by David Hutchins and titled, Self-Managing WorkGroups (with a subtitle of ‘Quality Circles as a vital key to participative management in TQM), a Quality Circle is defined as “…a small group of people under the same supervisor who does similar work and volunteer to come together as a group, usually for one hour per week in company time. They do this on a regular basis and are trained to identify, analyse, and solve work-related problems, with their supervisor as leader.”

This employee participation, beyond their day-to-day tasks, is a key element in recording success in business performance. In essence, the only way to achieve an optimal level in business performance is by engaging the brain power and job knowledge of all those that actually work in the organisation – according to:

- Konosuke Matsushita, the President of Matsushita Electric: ‘…to use every ounce of intelligence available in the organisation,’ and

Professor Ishikawa who also said, ‘…to bring out man’s infinite capabilities.’

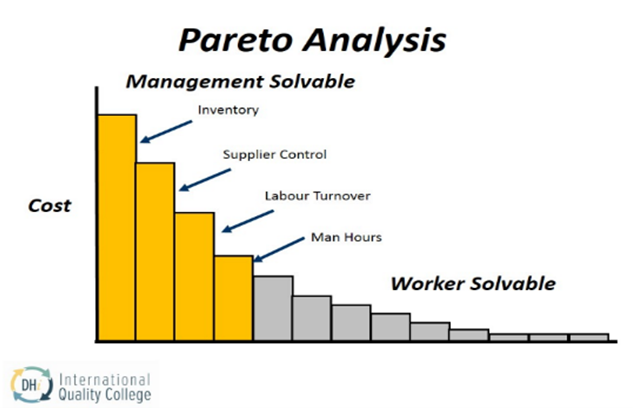

This principle is emphasised by Dr Joseph Juran’s ‘Pareto Analysis, where it shows that 80% of the problems in an organisation account for some 20% of the total causes, with responsibility for rectification of the total split between ‘management solvable’ and ‘worker solvable’ problems. This infers how TQM relates to the involvement of the entire workforce in Quality management. But it also illustrates the fact that Management solvable problems should be addressed early in the programme. This has the further advantage that when the workforce are also introduced to the problem-solving process, the managers will have a better understanding of what they are doing, and that they are approaching the workforce with clean hands!

The effect of having Quality Circles as an integral part of TQM necessitates the teaching of problem-solving tools and techniques that can include those of BPR, Lean Six Sigma, ITIL etc (hitherto, these had been reservedly taught to functional Quality Improvement teams) all the way to the base level employees of an organisation. This knowledge has helped to ensure that they gave attention to issues arising in their specific areas of work; hence, the ‘worker solvable’ problems were made fixable.

If this remaining 20% are not addressed, then it follows that those organisations that do not address this issue will potentially underperform against their rivals who give this attention to their employees accordingly.

GET™ Principals